First, let’s be honest: Electrification is not perfect for all locations, for all vehicle classes and for all routes. There are many applications where pursuing electrification will result in having to pay a substantial premium. However, when planned properly, real savings can be achieved.

A simplified look at the cost

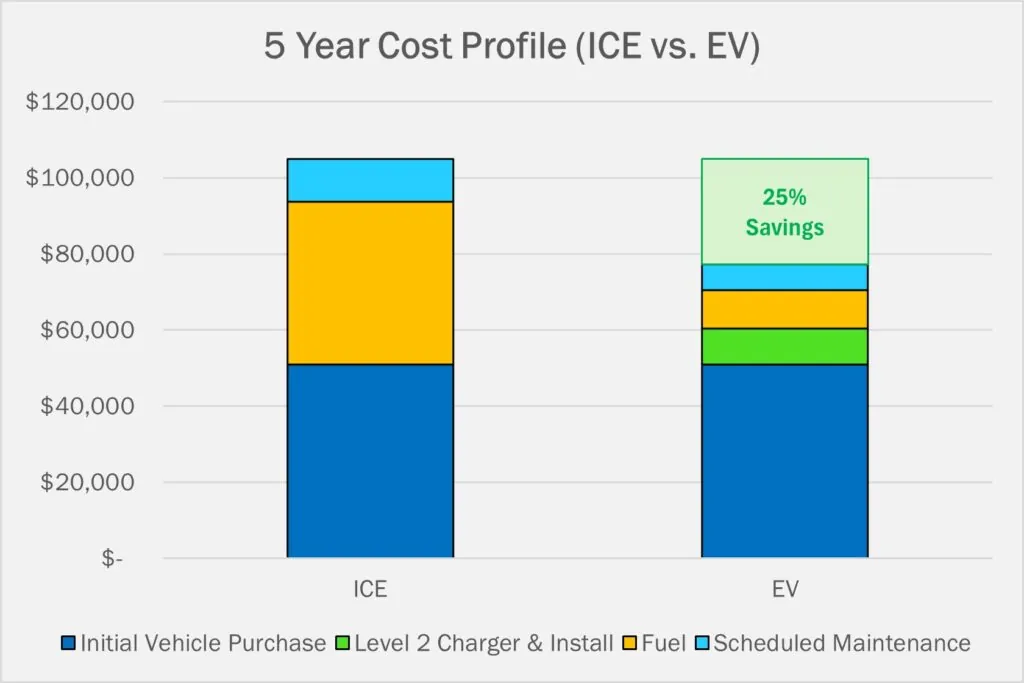

Conducting a Total Cost of Ownership (TCO) analysis of vehicles electrification can be cumbersome to model, complicated to understand and is not a tool that finance professionals use to evaluate investments. Instead, let’s take a simplified approach and focus on the key cost factors: Vehicle, Fuel, Maintenance, and Infrastructure – particularly with the Class 2 – 3 vehicle segment that makes up 88% of the market.

When evaluating electrification options, the vehicle generally represents over 75% of the capital cost, making it the logical starting point. Ford recently announced price parity between their ICE and EV models with the Lightning Pro model priced at parity with the F-150 4×4 crew cab and the E-Transit matching prices across the three variations of cutaway, chassis cab and low roof cargo vans. We can expect that with continued advances in battery density and continuing cost curve reductions, this is just the beginning of vehicle costs coming in line and eventually surpassing ICE models.

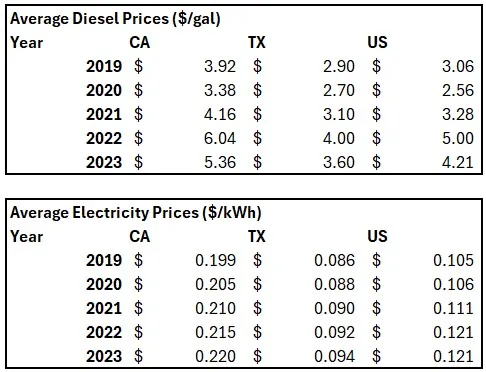

According to the Federal Energy Information Administration (EIA), over the last 5 years, the average electricity price in the US only increased 2.7% while the average diesel price increased 6.6%.

This trend also applies at the regional level. Texas and California are currently the largest commercial EV markets in the US, with a quarter of the total commercial EV stock operating on the road. California’s electricity rates increased 2.0% while diesel prices increased 6.5%. In Texas, electricity rates increased only 1.8% with diesel prices moving up 4.4%.

Maintenance requirements for Class 2 electric vans differ fundamentally from their ICE counterpart, largely due to far fewer moving parts, fewer fluids and simpler electronics. However, not all maintenance costs decrease. For example, our operating fleet has shown that tires experience greater wear and tear due to the faster acceleration and regenerative braking, but those added expenses are offset by overall maintenance savings and can be largely managed through driver training.

Infrastructure is a particularly unique cost consideration for electric vehicles that doesn’t apply to internal combustion engine vehicles. However, when Level 2 chargers are installed in locations with available rebates or make-ready incentives, the additional expense becomes minimal. Additionally, these infrastructure costs are more than offset by the fuel savings from using electricity instead of diesel. And for property owners, investing in onsite EV charging can be a competitive advantage—especially in industrial zones, where most commercial electric vehicles operate.

Bringing it together

Evaluating and stitching together the various components of fleet electrification to understand the economic opportunities can be daunting. The team at Revolv is able to find these pockets of value by applying our decades of fleet and infrastructure expertise and help companies realize savings that they can reinvest back into their core business.

Take action today

We’d be happy to discuss how it fits your operations and budget by conducting a free electrification study.